Polycarbonate (PC) is a widely used thermoplastic polymer product, which was first commercialized in the 1950s by Bayer Company of Germany and General Electric Company of the United States. Polycarbonate is a kind of copolymer, which is composed of several different types of monomers combined with each other.

Polycarbonate is divided into different grades according to strength and toughness. Polycarbonate has the highest impact resistance, excellent dimensional stability and thermal stability, excellent processability, stain resistance, non-toxicity, and low water absorption among thermoplastics. The high impact strength makes it able to withstand repeated hits, crushing and peeling.

This PC material mainly refers to the PC material (transparent) for injection molding, and the PC material for 3D printing is accessible now, with Stratasys FDM technology, the properties of the PC material is similar to each other, except for the color, the PC material for 3D printing is white.

Limitation

Unfortunately, although polycarbonate has strong impact resistance, it has poor scratch resistance. When PC is used for polycarbonate sheets, eyeglass lenses, and exterior parts of automobiles made of polycarbonate, it must be coated Hard coating.

Other limitations include:

• Poor fatigue durability

• Long-term exposure to water above 60℃ will weaken mechanical properties

• Susceptible to attack by hydrocarbons and alkalis

• Need to be properly dried before processing

• Prolonged exposure to ultraviolet light will turn yellow

• Poor creep resistance (can be improved by adding glass or carbon fiber reinforced materials)

Temperature characteristics

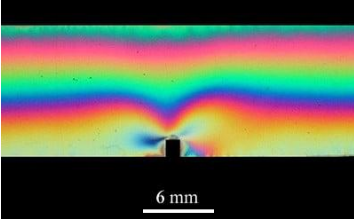

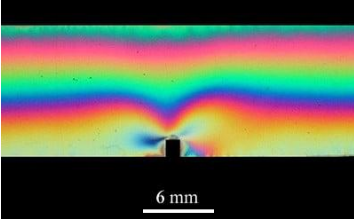

Strain-induced birefringence in notched polycarbonate rods

Strain-induced birefringence in notched polycarbonate rods

Polycarbonate can maintain performance in a wide temperature range (-20°C to 140°C). Its glass transition temperature is about 147°C, above which it will gradually soften and become fluid above about 155°C.

Standard polycarbonate resin should not be exposed to ultraviolet rays for a long time because it may become brittle. However, an ultraviolet stabilizer can be added to the main resin layer.

Processing

Polycarbonate is easy to process, 3D printing and mold, common methods of producing polycarbonate parts include:

• 3D printing

• Injection molding

• Thermoforming

Tools for making strain-free and stress-free products must generally be kept at high temperatures above 80°C.

Polycarbonate has the ability to plastically deform and will not crack or break. Unlike most plastics, 3D printing technology can be used to process polycarbonate at room temperature without heating. Therefore, it is particularly suitable for prototype applications compare to investing a huge cost for an injection mold, 3D printing delivers the same material properties and high accuracy model for prototype test.

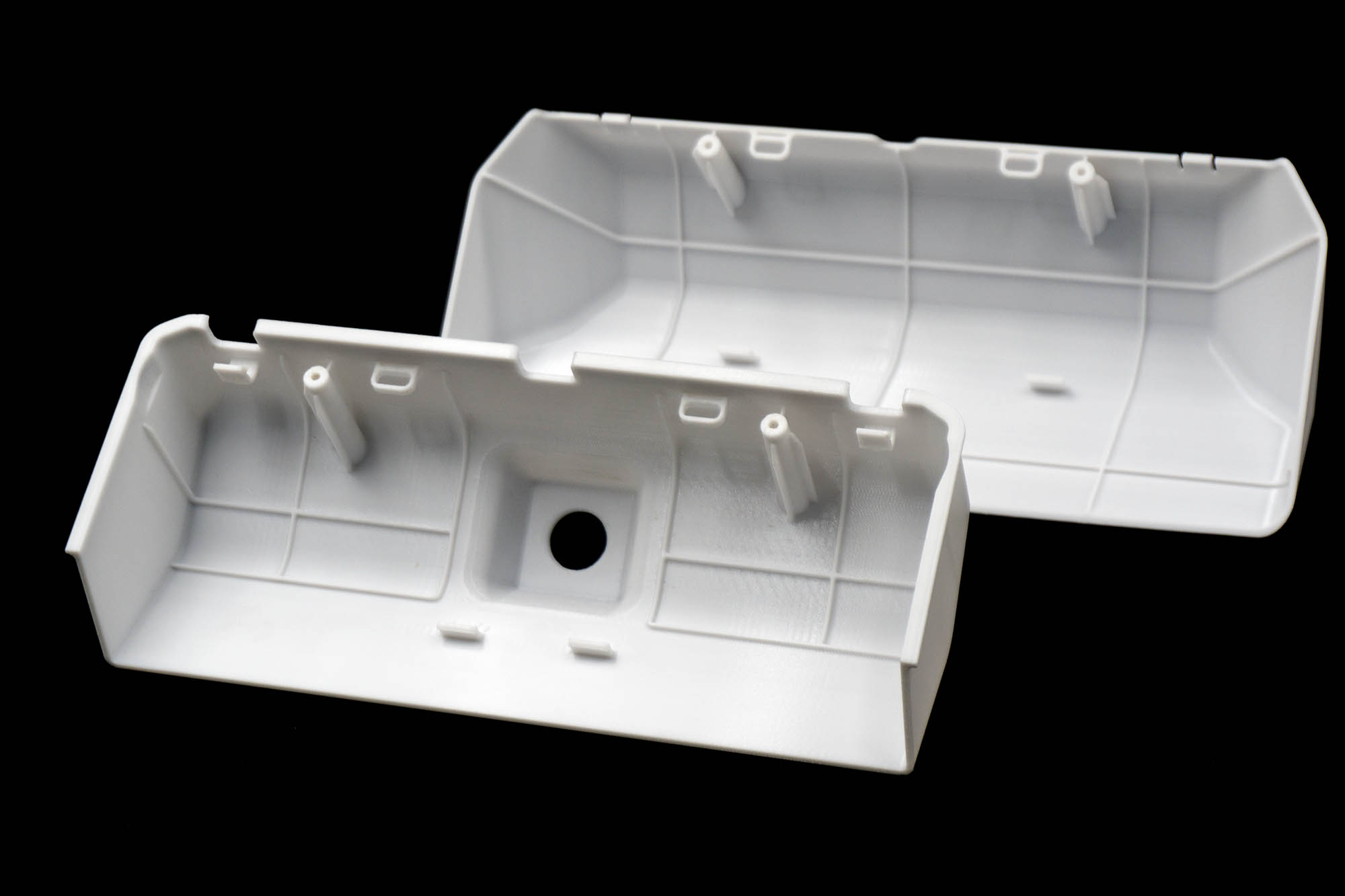

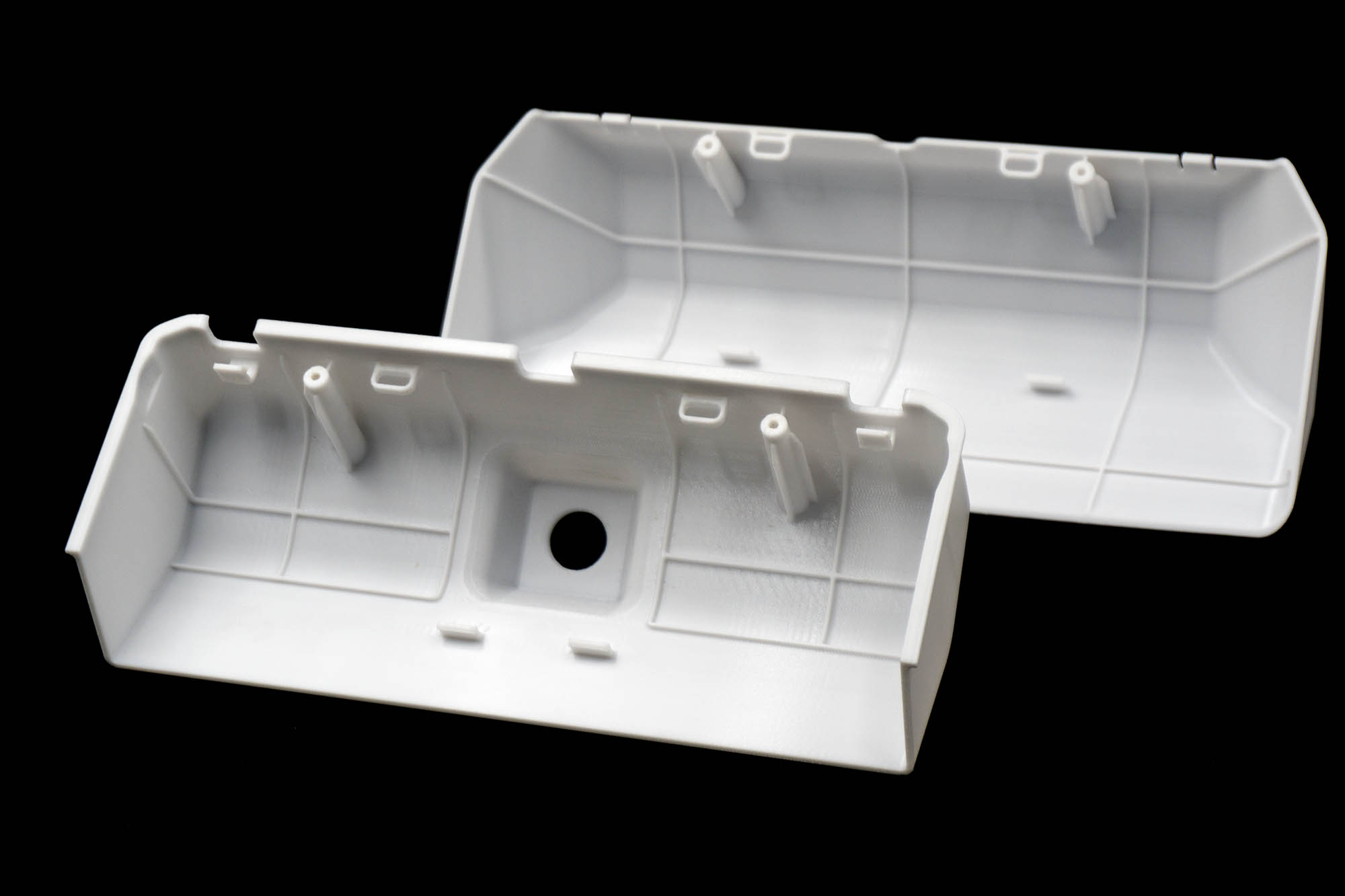

(PC material printed by Stratasys Fortus 450)

(PC material printed by Stratasys Fortus 450)

Electronic components, glass products, CD/DVD, optical reflectors, bottles, glasses, food containers, protective glasses, display screens, mobile phone shells, bulletproof "glasses". Color PC can reduce glare, for example, covering luminous street signs on the road, thereby protecting LEDs and reducing glare. Special grades can be used for medical applications after sterilization. PC-ISO is a biocompatible material that has passed ISO19300 verification and can be processed by 3D printing as a medical or food product.

3D Printing

PC is a commonly used material in the production of products, but due to the high price of making molds, traditional methods cannot use PC as a prototype to verify the functionality of the product. In this case, using 3D printing to make the initial model is a better choice. Except for Stratasys FDM machines, almost no other 3D printing methods can print PC materials. If you only need to test the mechanical performance of the PC model, then our Stratasys machine can meet your needs. If you need to test transparent appearance parts, we also provide transparent resin materials from Stratasys as an option.