3D printing has revolutionized the manufacturing industry, providing a wealth of opportunities for creating complex, intricate designs with relative ease. This disruptive technology has come a long way since the advent of Fused Deposition Modeling (FDM) in 1988. However, it wasn't until 2009, when the FDM patent expired, that the 3D printing landscape experienced a significant shift. This paved the way for the introduction of the Fused Filament Fabrication (FFF) process, enabling more accessible and cost-effective 3D printing solutions.

Despite their superficial similarities, these two processes have distinct characteristics, offering unique advantages and disadvantages that can significantly impact the quality, strength, and precision of the printed parts. Misunderstandings or misconceptions about these techniques may lead potential users to overlook the benefits of each and settle for an inferior 3D printing process.

A Deep Dive into FDM and FFF Processes

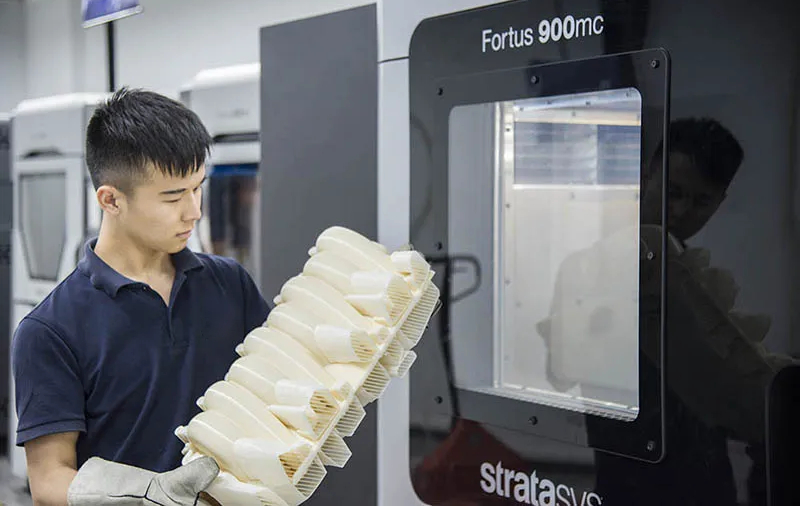

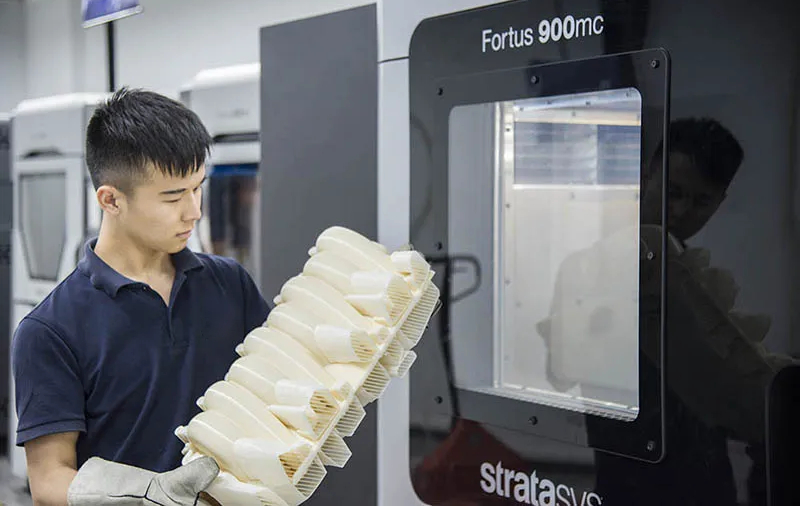

FDM technology, used by industry giants like GE, Airbus, BMW, and Ford, is characterized by its use of large, enclosed machines capable of producing high-quality, industrial grade prototypes. These machines can maintain consistent tolerances of ±. 127 mm (±. 005 in.), which is among the highest of any 3D printing technology on the market.

On the other hand, FFF printing typically serves applications that require form and visual validation prototypes. These machines may not maintain consistent tolerances, which may lead to a negative perception of the technology, particularly among engineers, designers, and other professionals new to the 3D printing field.

On the other hand, FFF printing typically serves applications that require form and visual validation prototypes. These machines may not maintain consistent tolerances, which may lead to a negative perception of the technology, particularly among engineers, designers, and other professionals new to the 3D printing field.

Examining the Core Differences

One of the key factors distinguishing FDM from FFF lies in the printing chamber. FDM printers house the deposition process within a print chamber maintained at high temperatures, which greatly improves mechanical properties and prevents warping and curling during the deposition process. Conversely, FFF printers do not feature a heated chamber, leading to the generation of residual stresses in the printed part and potentially impacting the quality, strength, and precision of the final product.

Material selection is another critical aspect. FDM can print with some of the strongest commercially available plastic materials, including Polycarbonate, Nylon, ULTEM, and PEEK. This is possible due to FDM's enclosed ovens and strict filament quality control processes, ensuring consistent diameters and material quality. FFF printers, however, often work with lower-quality filaments that may lack consistency, affecting the overall quality and accuracy of the print.

Material selection is another critical aspect. FDM can print with some of the strongest commercially available plastic materials, including Polycarbonate, Nylon, ULTEM, and PEEK. This is possible due to FDM's enclosed ovens and strict filament quality control processes, ensuring consistent diameters and material quality. FFF printers, however, often work with lower-quality filaments that may lack consistency, affecting the overall quality and accuracy of the print.

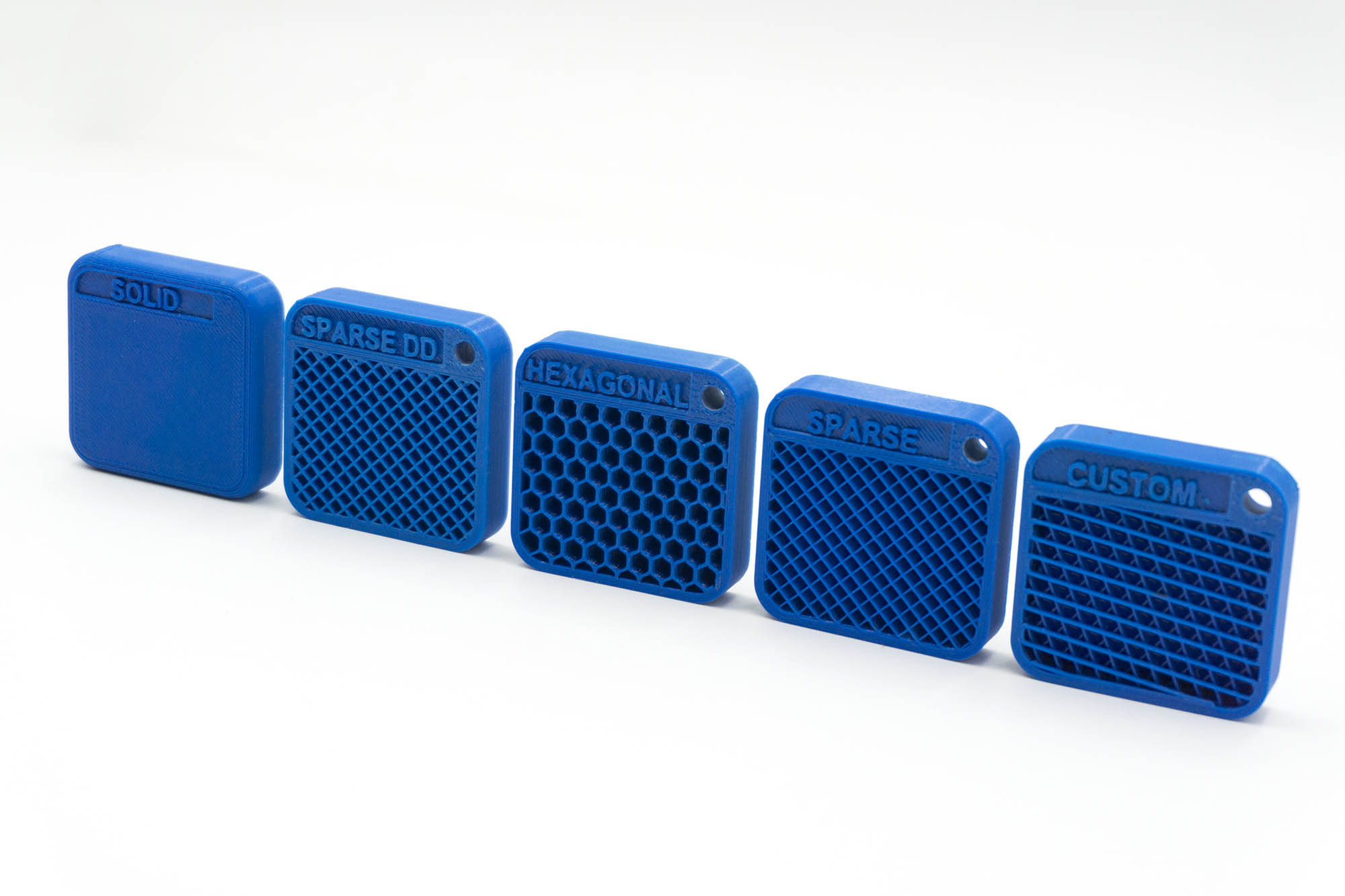

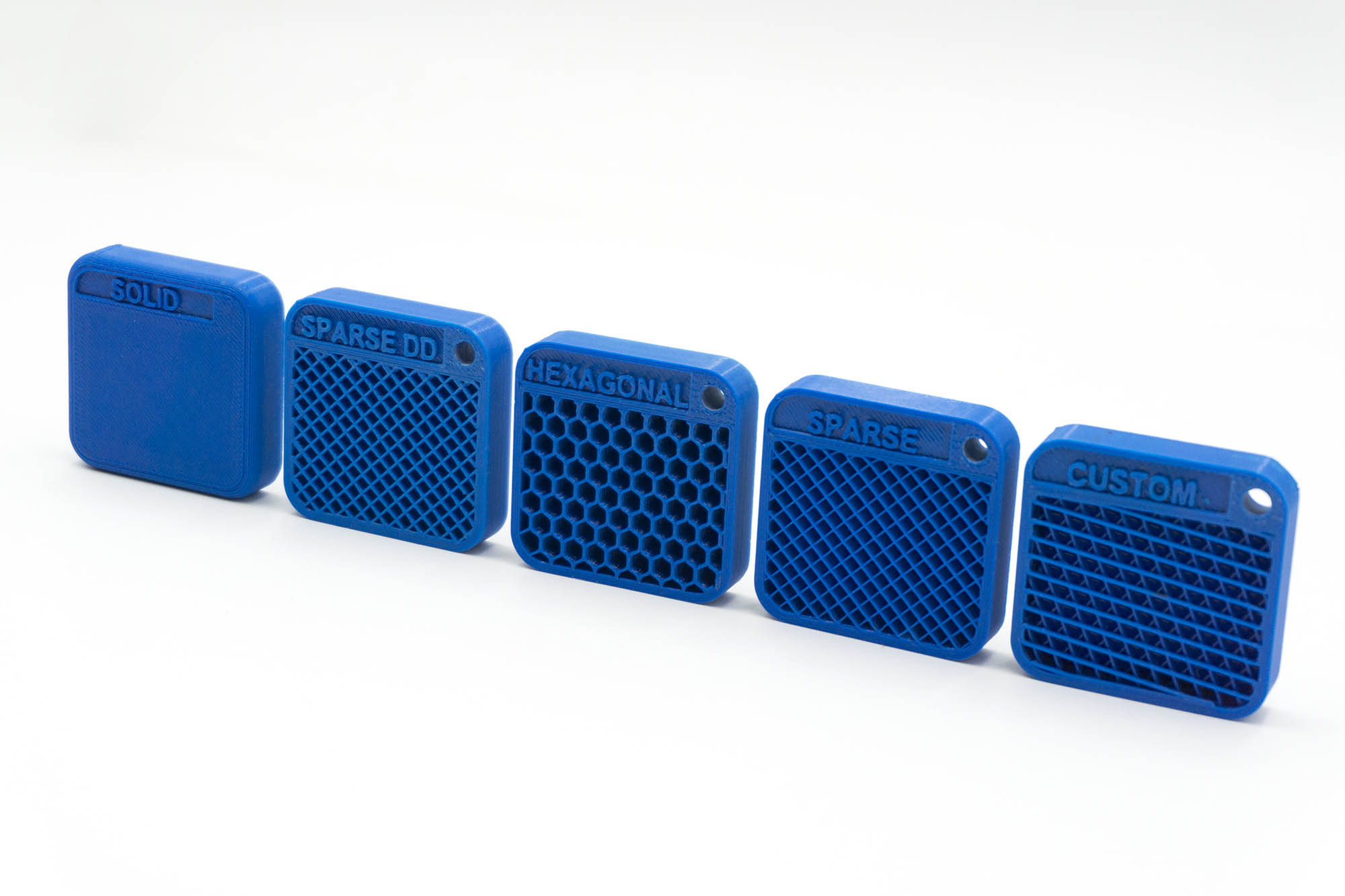

Lastly, the support materials used by each technology differ significantly. FDM printers use soluble support materials designed specifically for each thermoplastic, ensuring perfect results. On the other hand, FFF printers often use PVA, a water-soluble material, which can lead to issues of delamination, warping, and quality when supporting higher temperature materials.

Lastly, the support materials used by each technology differ significantly. FDM printers use soluble support materials designed specifically for each thermoplastic, ensuring perfect results. On the other hand, FFF printers often use PVA, a water-soluble material, which can lead to issues of delamination, warping, and quality when supporting higher temperature materials.

Understanding these nuances is key to selecting the right 3D printing technology for your needs. Both FDM and FFF have their unique strengths and limitations, which can be leveraged or mitigated depending on the specific application requirements. Therefore, a comprehensive understanding of these processes can lead to more effective and efficient use of 3D printing technology.