3d Printing Service Industry News

MJF vs FDM: Deciphering the Differences Between HP and Stratasys's 3D Printing Techniques

3D printing has revolutionized how objects are designed and manufactured. Among various 3D printing technologies, HP's Multi Jet Fusion (MJF) and Stratasys's Fused Deposition Modeling (FDM) are leading the way. But, how do they differ? What are their individual advantages, and how can you decide which is the right fit for you? Let's delve into these technologies to provide a comprehensive comparison and understanding.

1. Understanding the Technologies:

MJF (Multi Jet Fusion):

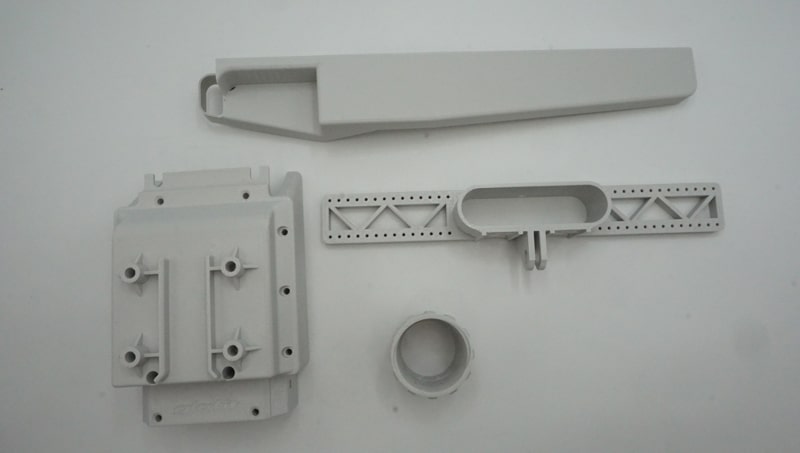

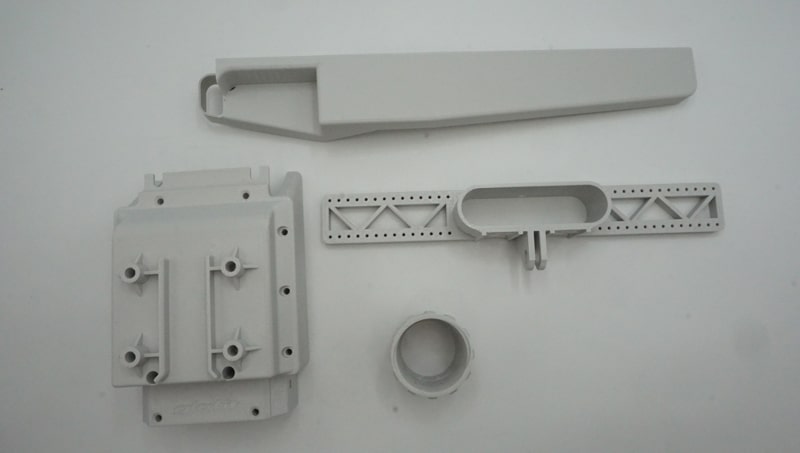

MJF, developed by HP , is a powder bed fusion process. It works by selectively applying a fusing agent on a layer of material powder, which is then fused using infrared energy. This results in parts with high detail and smoothness.

FDM (Fused Deposition Modeling):

Stratasys's FDM is one of the most commonly used 3D printing techniques. It works by extruding thermoplastic materials layer by layer, following a predetermined path, to build the object from the ground up.

2.What Materials are Used?

MJF primarily uses Polyamide (PA) 12, PA11, creating strong, durable, and flexible parts. With MJF, you can also print with materials that are glass-beaded or filled with other substances to alter properties like stiffness or thermal conductivity.

FDM uses a wider range of thermoplastic materials, including ABS, Nylon, and more high-performance engineering plastics like ULTEM . The ability to use soluble support materials is another significant advantage of FDM.

3. Advantages and Unique Features:

MJF:

Speed: Due to its simultaneous fusion across the whole layer, MJF is generally faster than other 3D printing techniques.

Detail and Surface Finish: MJF offers parts with high detail and a smoother finish compared to FDM.

Material Reusability: Unused powder can be recycled for future prints, reducing waste.

FDM:

Material Versatility: The range of filaments available means that FDM can cater to various applications from prototypes to end-use parts.

Ease of Use: FDM printers are typically user-friendly, making them popular among hobbyists and professionals alike.

Cost-Efficiency: FDM printers and materials are generally more affordable, making them a go-to choice for budget-conscious users.

4.What are their Advantages and Features?

MJF offers significant benefits like high productivity and speed, thanks to its ability to print entire layers simultaneously. Moreover, it produces highly accurate, robust parts with fine details and excellent surface finishes. MJF's use of PA provides the printed parts with high heat resistance, making them suitable for a wide range of industrial applications.

FDM, on the other hand, stands out for its simplicity, low cost, and material variety. The parts printed via FDM can withstand mechanical stress, making it ideal for prototyping and functional testing. Moreover, it's excellent for creating large parts and complex geometries due to its ability to print with soluble support materials.

Both MJF and FDM have unique advantages, with MJF offering high speed, quality, and precision, and FDM providing simplicity, cost-effectiveness, and a wider material range. Your choice between the two should primarily depend on the specific needs of your project. By considering the factors of application, material requirements, budget, and precision, you can choose the 3D printing technology that best suits your objectives.