ULTEM™ 9085 resin is a flame-retardant high-performance thermoplastic for digital manufacturing and rapid prototyping. It is ideal for the transportation industry due to its high strength-to-weight ratio and its FST (flame, smoke and toxicity) rating. This unique material’s certifications make it an excellent choice for the commercial transportation industry. Combined with a Fortus® 3D Production System, ULTEM 9085 resin allows design and manufacturing engineers to produce fully functional parts that are ideal for advanced functional prototypes or end use without the cost or lead time of traditional tooling. For high-quality parts that meet stringent aerospace industry requirements, ULTEM 9085 Aerospace is available

ULTEM™ 1010 resin offers the highest heat resistance, chemical resistance and tensile strength of any FDM thermoplastic. It is the only FDM material with an NSF 51 food-contact certification, and it’s biocompatible with an ISO 10993/USP Class VI certification, this unique material’s pre-existing certifications make it an excellent choice for the commercial transportation industry, especially: Aerospace, medical, marine and ground vehicles.

Now I believe you have got the impression and understanding about the Ultem material right?

Follow me, I’ll take you know the safety of flammability for Ultem material

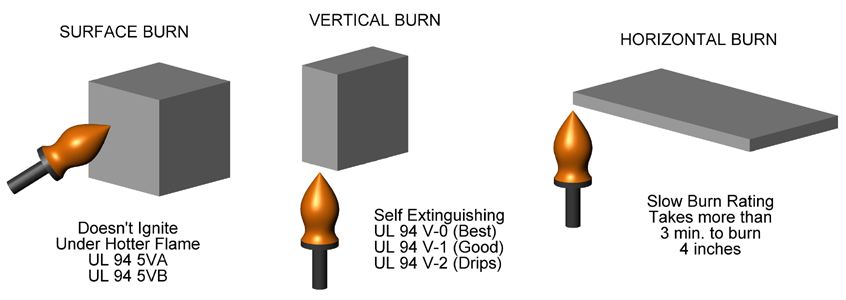

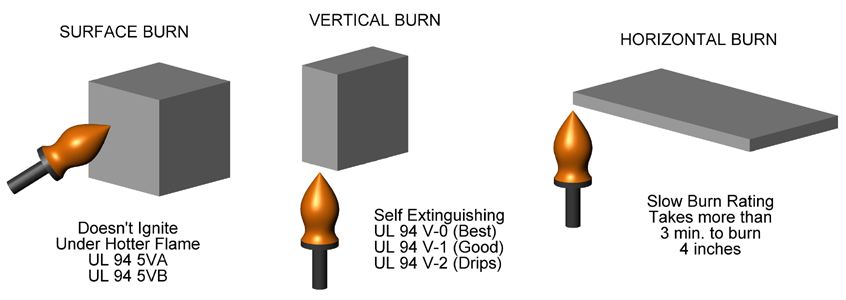

What is FST?

Yes you are right, as mentioned above it is flame, smoke and toxicity

And how do we rating the the safety of Flammability? Depends on the time how long the flame last.

V-2(Drips) the drips may not burn with the flame combustion for more than 30 seconds amd the total flaming combustion time may not exceed 250 seconds.

V-1(Good)the drips may not burn with the flame combustion for more than 30 seconds amd the total flaming combustion time may not exceed 250 seconds. Yes similar to V-2

What is the Requirements for FST Rated V-0,please take a close look on it.

1.The specimens may not burn with flaming combustion for more than 10 seconds after either application of the test flame.

2.The total flaming combustion time may not exceed 50 seconds for the 10 flame applications for each set of 5 specimens.

3.The specimens may not burn with flaming or glowing combustion up to the holding clamp.

4.The specimens may not drip flaming particles that ignite the dry absorbent surgical cotton located 300 mm below the test specimen.

5.The specimens may not have glowing combustion that persists for more than 30 seconds after the second removal of the test flame.

Other Benefits of Ultem Material

1.High-Performance Thermoplastic with High Heat Applications

2.Thermal and Chemical Resistance

3.Chemical Resistance

4.FST Rated V0

5.Sterilized

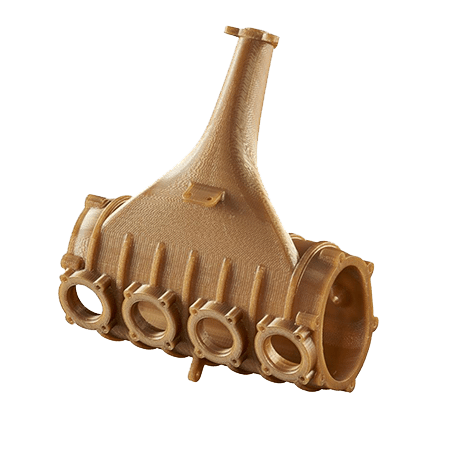

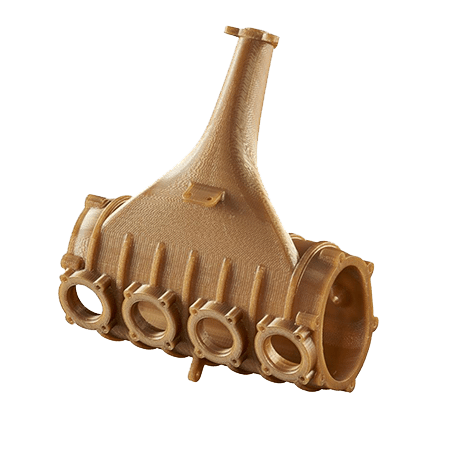

Applications of Ultem Material

1.Functional Prototypes

2.Aerospace Applications

3.Automotive Applications

4.Aircraft Interior Components and Ductwork

5.Food Packaging

6.Medical Housings and Packaging (Sterilization)

7.Direct Digital Manufacturing (DDM)

8.Applications Requiring FST Rating